Polyaluminium ferric magnesium spray dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

LPG series high speed centrifugal spray dryer is a special drying equipment suitable for liquid drying of emulsion, suspension, paste and solution. In polymers and resins: dyes, pigments: ceramics, glass, rust removers, insecticides: carbohydrates, dairy products: detergents and surfactants; fertilizers: organic compounds, inorganic compounds, especially in the drying.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

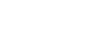

Through the filter and heater, the air enters the air distributor at the top of the dryer, and the hot air enters the dryer in a spiral shape. The feed liquid is pumped to the centrifugal atomizer of the dryer from the feed liquid tank through the filter, so that the feed liquid is sprayed into a tiny mist like liquid drop. The feed liquid and hot air flow in parallel, and the water evaporates rapidly, and the product is dried into a powder like product in a very short time. The finished product is discharged from the bottom of the drying tower and the cyclone separator, and the waste gas is discharged from the fan.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| project | LPG-5 | LPG-25 | LPG-50 | LPG-100 | LPG-150 | LPG-200 | LPG-500 | LPG800 -10000 |

| Maximum water evaporation(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800-10000 |

| Spray form | 高速离心雾化器 | |||||||

| Atomizer speed(rpm) | 25000 | 18000 | 16000 | 11000-13000 | ||||

| Atomizing disc diameter(mm) | 50 | 120 | 150 | Determined according to process requirements | ||||

| Tower diameter(mm) | 0.9 | 1.75 | 2.3 | 2.7 | 3 | 3.2 | 4.7 | |

| Electrothermal power (kw) | 9 | 31.5 | steam+18 | steam+36 | steam+54 | Determined according to process requirements | ||

| heat source | Optional electric, steam + electric, oil, coal, gas hot blast stove | |||||||

| size (LxWxH)m | 1.6×9.1 ×1.75 | 4×2.7 ×4.5 | 4.5×2.8 ×5.5 | 5.2×3.5 ×6.7 | 7×5.5 ×7.2 | 7.5×6 ×8 | 12.5×8 ×10 | Design and layout according to site conditions |

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

Fast drying speed, generally only 5-15 seconds, with instantaneous drying characteristics;

The drying process of the material is completed in a short time, which is suitable for the drying of the heat sensitive material, and can keep the color, fragrance and taste of the material. The purity and quality of the finished product are high.

The production process is simplified, the operation control is convenient, and it is suitable for continuous control of production; the liquid with moisture content of 40% - 90% is dried into powder at one time to reduce the crushing, screening and other processes.

The dispersion, fluidity and solubility of the product are good, and the particle size, bulk density and water content of the product can be adjusted within a certain range.

The purpose of fast drying is that the two wind can avoid sticking phenomenon and effectively improve the thermal efficiency of spray drying. The upward wind enters the hot air distributor from the top of the spray drying machine, and then the hot air is evenly distributed into the drying chamber by the distributor, and the spiral movement is carried out. At the same time, the liquid is dispersed into droplets through the function of the centrifugal atomizer, so that the contact surface between the droplet and the hot air increases, and the process of heat exchange is accelerated, so that the water content of the material evaporates rapidly, and the material completes drying in a very short time. 。 The lower intake air enters from the bottom of the spray drying machine, and the air outlet is designed with the air distribution device. The rotation direction of the hot air and the atomizer is reverse, reducing the radius of the droplet trajectory, reducing the product sprayed onto the wall, and increasing the time of the droplet in the air and improving the efficiency.

After drying, the finished products are discharged from the lower part of the cone of the drying tower, and a part of fine dust is brought out from the exhaust port with air. The gas and solid are separated through the cyclone separator. The fine dust is discharged from the discharge port at the lower part of the cyclone, and the clean air is discharged from the exhaust port at the top of the cyclone separator. After drying, all finished products are sent to the next process through the air flow conveying system.

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

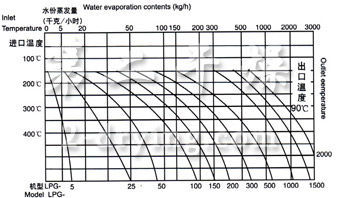

C

urve

CURVE

Reliable supplier of drying equipment users

urve CURVE

|  |

用户:宜宾天蓝化工有限公司 用户:宜宾天蓝化工有限公司 |  ø8000×17000 喷雾塔, 蒸发量3000KgH2O/h |

ø7200x17000 喷雾塔 |  中信国安科技公司 国内特大型离心式喷雾干燥,塔体直径17米,高度38米,单台塔一小时处理17吨液体物料,共八套现场制作图。 配套1600万大卡直接式天然气热风炉,进风温度450度。 |